How to move IBP from a Tedious Process to an Executive Decision Factory

When I was IBP manager at a multi-billion-dollar CPG company about 10 years ago, I remember a marketing director telling me just before the executive IBP meeting; ‘Niels, this feels like going to the dentist every month’.

I agreed with him. Back then, preparing for a monthly IBP meeting was a painful, tedious effort, with my full planning team consumed and running overtime to get the IBP decks out in time. An environment with multiple ERP and APS systems to gather our data did not help. A visit to the dentist was probably more fun indeed!

Once we were in the meeting, the marketing director as P&L owner and I would be happy to be able to get through the KPI dashboard, the NPD pipeline and a feasible volume and value projection of the categories we were responsible for. It was a lot of FYI. If we were lucky some decisions were being made, but none were executive paygrade decisions really.

Since then a lot has changed…and a lot has not!

What has not changed for Integrated Business Planning

What unfortunately has not changed, is that preparing an IBP deck is often still a tedious piece of work. Companies now have even more ERP, APS, data lakes and other systems to gather IBP data from. For some global companies we talk about dozens! A recent study suggests that supply chain planners spend 50% of their time on data gathering and tinkering with it. Knowing this, who wants a job in supply chain planning when you just finished your degree? How can supply chain attract the best talent when all you do is tying data together?

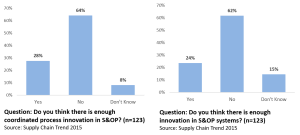

A lack of IBP process and system innovation was definitely the feedback I got in my 2015 and 2017 S&OP Pulse Check, where 64% of respondents thought there wasn’t enough IBP process innovation and 62% thought there wasn’t enough system innovation.

Although some new ideas are popping up lately, the IBP process itself has indeed not really evolved all that much in the last ten years. I still see a lot of that same IBP process slide that has been around for 30 years. Because of a lack of process innovation, partially driven by overzealous IBP process compliance, IBP remains more of a process factory rather than an executive decision factory.

What has changed for Integrated Business Planning

Although the feedback by IBP practitioners was a lack of system innovation to support them, a lot has changed since then. Back then, Big Data was still a hype with not too many relevant business cases. Now machine learning algorithms are integrated in many planning systems and happily chew away at Big Data to come up with planning improvement suggestions. We see examples of digital planning twins, where the underlying planning process is fully digitised, so it can be autonomous or ‘no-touch’. Cognitive automation has become a reality, supporting planners with complex planning decision making at scale and speed. This can now be done across the dozens of ERP and APS systems as smart data crawlers can create one common IBP data layer across the whole enterprise, accessible at real-time in the cloud. Those same data crawlers can write back information and decisions, making a planning process self-driving where this is valuable to do so.

What has changed recently, is that COVID19 has woken the world up to global supply chain dependencies, increased demand and supply disruption and a need for both supply chain resilience and strategic agility. Keeping a supply chain and company strategy intact and relevant in this environment is the main challenge in this new normal. IBP ought to deploy a company’s strategy, however the old, tedious monthly process will not suffice anymore to support this goal in our fast-changing world.

How to align the IBP process with technology

What we’ve witnessed the last 10 years is asymmetric innovation in IBP processes and supporting systems. Whilst new planning systems are shooting for the stars, making things possible I could only dream of before that IBP meeting 10 years ago, the process has not evolved with it. As proponents and drivers of the IBP process, trying to take the rest of the business in our IBP-slipstream, supply chain professionals and consultants only can blame themselves for this.

For decades the IBP process was leading, now technology is leading. How can the IBP process catch-up?

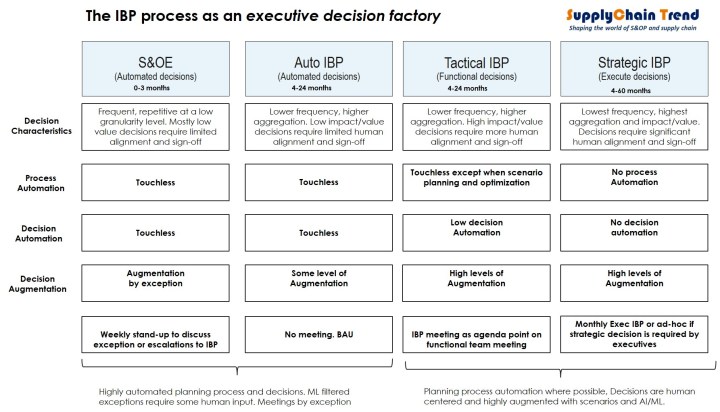

To make IBP an executive decision-making process it ought to be, answering complex questions at the speed of a business in the 21st century, supported by finite planning resources, my suggestion is to segment the IBP process in four elements as per below diagram. As we want to make IBP a decision making factory, the segments are based on decisions characteristics.

Continue reading “How to move IBP from a Tedious Process to an Executive Decision Factory”